Case study: Custom Die-Cut Paint Masking Solution

Development of a specialised custom masking solution for a leading injection moulder to streamline t…

Delivering cost-effective & efficient weld protection during shot-blasting of high-performance aerospace components

"This project is a great example of the value that a custom die-cut masking solution can deliver. Our specialist knowledge and expertise combined with a thorough understanding of our customer’s processes led to significant cost savings and process improvements”

Wayne Matthews, Head of Business Development

A major aerospace manufacturer was experiencing weld damage during shot-blasting due to ineffective manual masking methods, resulting in inconsistent protection, poor adhesion, and significant inefficiencies on the production line.

They contacted Tecman for a robust alternative, drawing on our expertise in masking solutions for critical manufacturing processes. Their existing workaround involved manually cutting and applying masking tape to the welded areas before shot-blasting the product. This approach was not only inefficient and unreliable, but also led to quality issues due to the tape occasionally peeling off mid-process, likely as a result of the adhesive type not being professionally specified for the application.

To effectively address the challenge, Tecman engineers sat down with the customer to fully understand the current workaround and the shot-blasting processes, as well as the intricacies of the product and each individual weld.

Protecting the welds during the shot-blasting process was critical to maintaining the structural integrity and overall quality of the product.

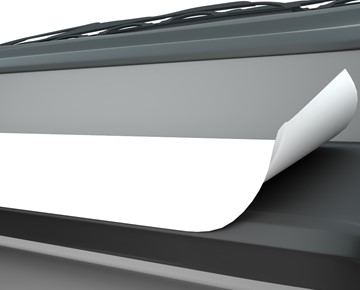

Recognising the demanding nature of the environment and the need for consistent, reliable protection, we specified 22-CR05, an extra heavy-duty crepe masking tape engineered for exceptional abrasion resistance and strong adhesion.

This material ensured complete and consistent coverage, significantly reducing the risk of weld damage during the shot-blasting process. Additionally, extensive testing confirmed that no adhesive residue remained on the welds, eliminating the risk of disruption to downstream processes.

In collaboration with the customer, our engineers designed over a dozen individual masking components, each tailored to protect a specific weld on the product. This customised approach ensured full and consistent protection of weld integrity during shot-blasting. To further improve operator efficiency and reduce application time, each complete set of components was supplied in a user-friendly sheet format, supported by a clear application map.

Tecman’s die-cut masking tape solution delivered significant cost savings for our customer by improving their process efficiency and increasing shot-blast output. Ease of application, reduced rework and downtime, and the assurance provided by extensive testing were key drivers behind this improvement.

Additionally, the custom masking components provided reliable weld protection, enhancing shot-blast consistency and the quality of the finished product.

By combining our customer-focused approach with engineering expertise, innovative capabilities, and in-depth material knowledge, we helped our customer reduce quality issues, increase productivity, and achieve meaningful overall cost reductions.

Faced with inconsistent manual masking and process inefficiencies, the customer was looking for a proven partner for a custom solution. Tecman's specialised masking expertise, demonstrated through the recommendation of high-performance materials and collaborative design of precise die-cut masking components, delivered tangible value.

Our focus on delivering process improvements and ensuring reliable weld protection in the demanding aerospace environment made us the ideal choice for a cost-effective and efficient solution.

We support our customers through every stage, from material selection and design phases to choosing the right manufacturing processes. This ensures the delivery of an optimised, cost-effective solution designed to effectively overcome challenges and deliver tangible benefits.

If your application could benefit from cost savings, process improvements, material enhancements, and product advancements, reach out to our experts to discover how we can support your application.

Development of a specialised custom masking solution for a leading injection moulder to streamline t…

Customised, die-cut paint masking solutions to protect components or surfaces during the painting pr…

Developed a solution with a major automotive OEM to protect piano black paint during manufacturing p…

Many of the processes that go into fabricating high-performance vehicles remain largely unsung, prov…

High quality masking tapes covering a wide range of requirements from fine line automotive paint mas…

Design & manufacture of a custom die-cut adhesive gasket to bond a plastic component to a vehicl…

Increasingly sophisticated military and aerospace systems and devices require greater performance an…

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…