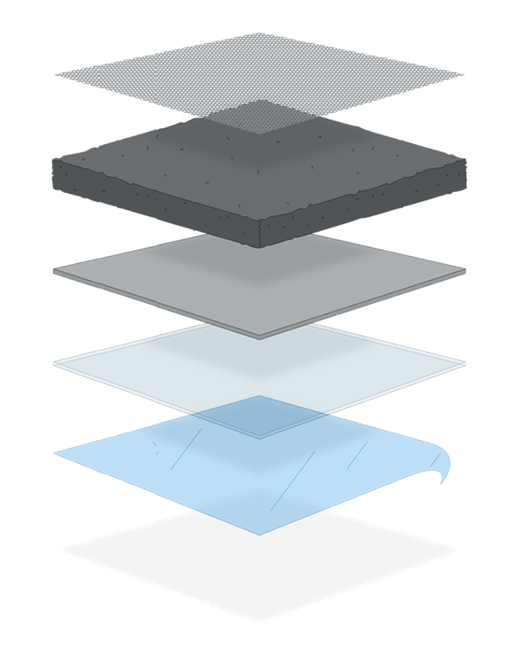

Multi-Layer Lamination

Advanced multiple material lamination facilities used for material preparation and final product manufacture, enabling the formulation of products outside of any standard product range. This capability allows us to apply PSA adhesives onto rigid and flexible substrates, with final format as rolls or sheets.

advanced die-cut multi-layer lamination techniques

Having the ability to laminate multiple layers, eliminates the requirement for multiple processing of the materials.

At our in-house conversion facility we combine multi-layer lamination techniques with innovative die-cutting processes. This enables unrestricted design capabilities, removes limitations and supports engineering creativity.

multiple material lamination

- Ability to laminate up to 1600mm width and up to six different material layers in one pass

- Specialised in the lamination of a wide range of advanced materials, including films, foils, foam and nonwoven materials

- Zone lamination provides the facility to create specific areas of adhesive on materials, often used to improve the handling of components during application and placement

Key benefits:

- Customisation

- Enhanced performance

- Innovative design

- Reduced component count

- Cost-optimisation

- Complex structures

die-cut multi-layer lamination Parameters

Multi-layered Components

The Development of multi-layer laminated Die-Cuts

Laminating & Die-Cutting

Our multi-layer lamination and die-cutting process provides Design Engineers with unrestricted design capabilities by removing limitations and supporting engineering creativity.

Multi-layer Lamination

Using multi-layer lamination and innovative conversion techniques, we create multi-layered parts with up to 6 layers to the exact drawings specified by Design Engineers.

Innovative Die-cutting Techniques

Precision die-cut parts are produced to specific requirements providing endless possibilities, including self-adhesive parts designed to maximize surface contact to components for a superior bond.

Optimised Solutions

The final part is formatted to optimise the application. Using this strategic approach ensure overall costs and wastage are reduced during the assembly process.

advanced materials

materials we convert into value added components

Adhesive Tapes

We have the flexibility to convert all our industrial double-sided adhesive tapes into customised solutions for customer specific bonding and mounting applications, available in various formats, including die-cut components, rolls, sheets, and adhesive pads.

Learn More

Surface Protection

Tecman’s range of high performance surface protection film and masking tapes are used to protect surfaces during manufacturing processes in demanding industries such as automotive, electronics, and wind blade protection in the renewable energy sector.

Learn More

Foam & Acoustic Materials

Our high-performance foam and acoustic materials are converted into custom components for a wide range of industries and applications, including sealing and cushioning, through to NVH management in electric vehicle powertrains.

Learn More

Thermal Management Products and Materials

Our portfolio of thermal management materials and products include thermal cell barriers, thermal interface materials and other thermally and electrically conductive materials for critical applications such as thermal management in EV battery packs.

Learn More