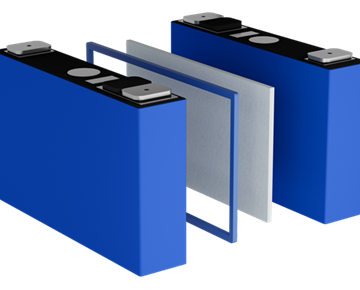

Advanced thermal runaway barriers

Effective thermal runaway barriers are essential for optimising cell performance, longevity, and saf…

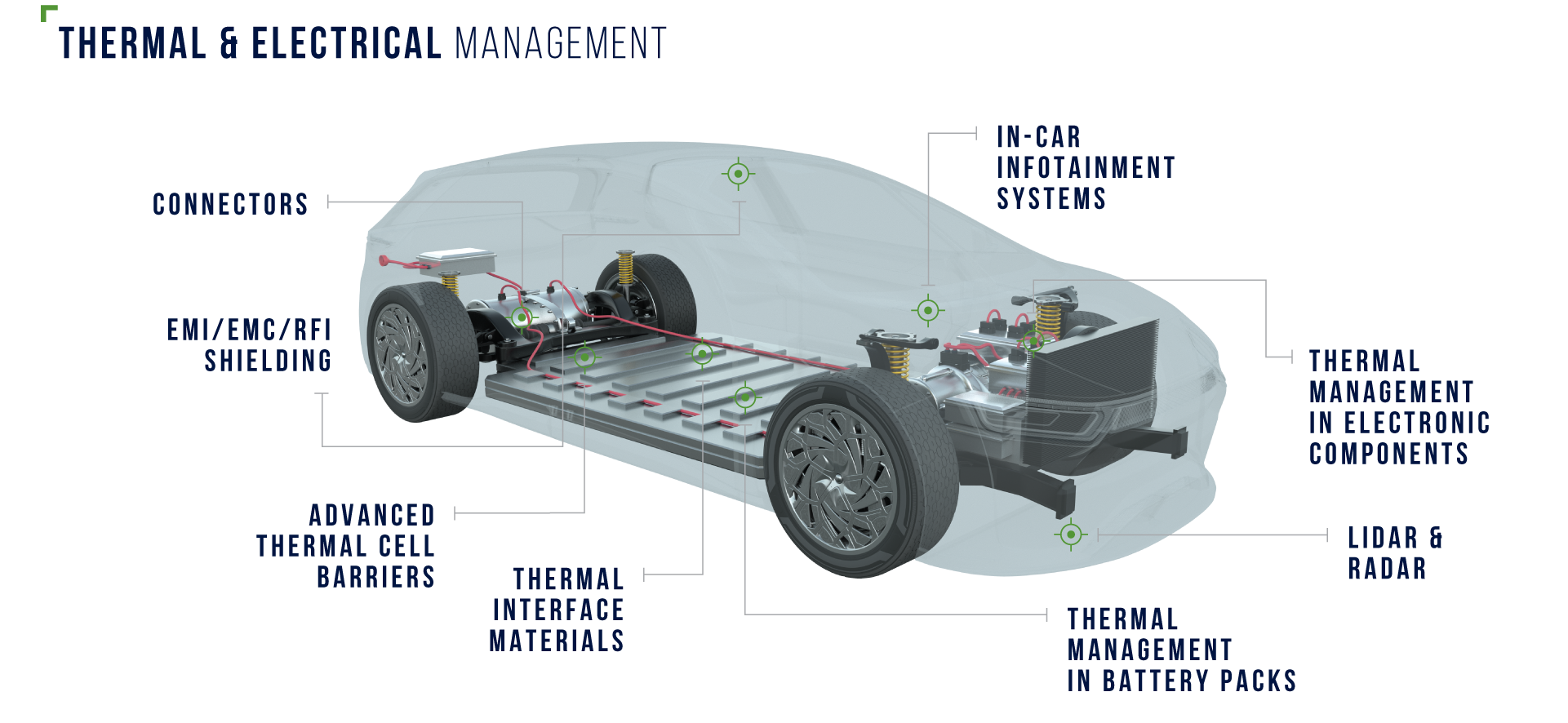

Unlock electric mobility performance & innovation with superior thermal & electrical management solutions

Increasingly sophisticated vehicle electronics need leading edge materials to meet complex application requirements. We have years of experience in solving thermal management and electrical management challenges across multiple industries, designing and manufacturing millions of engineered components to exceed customer expectations.

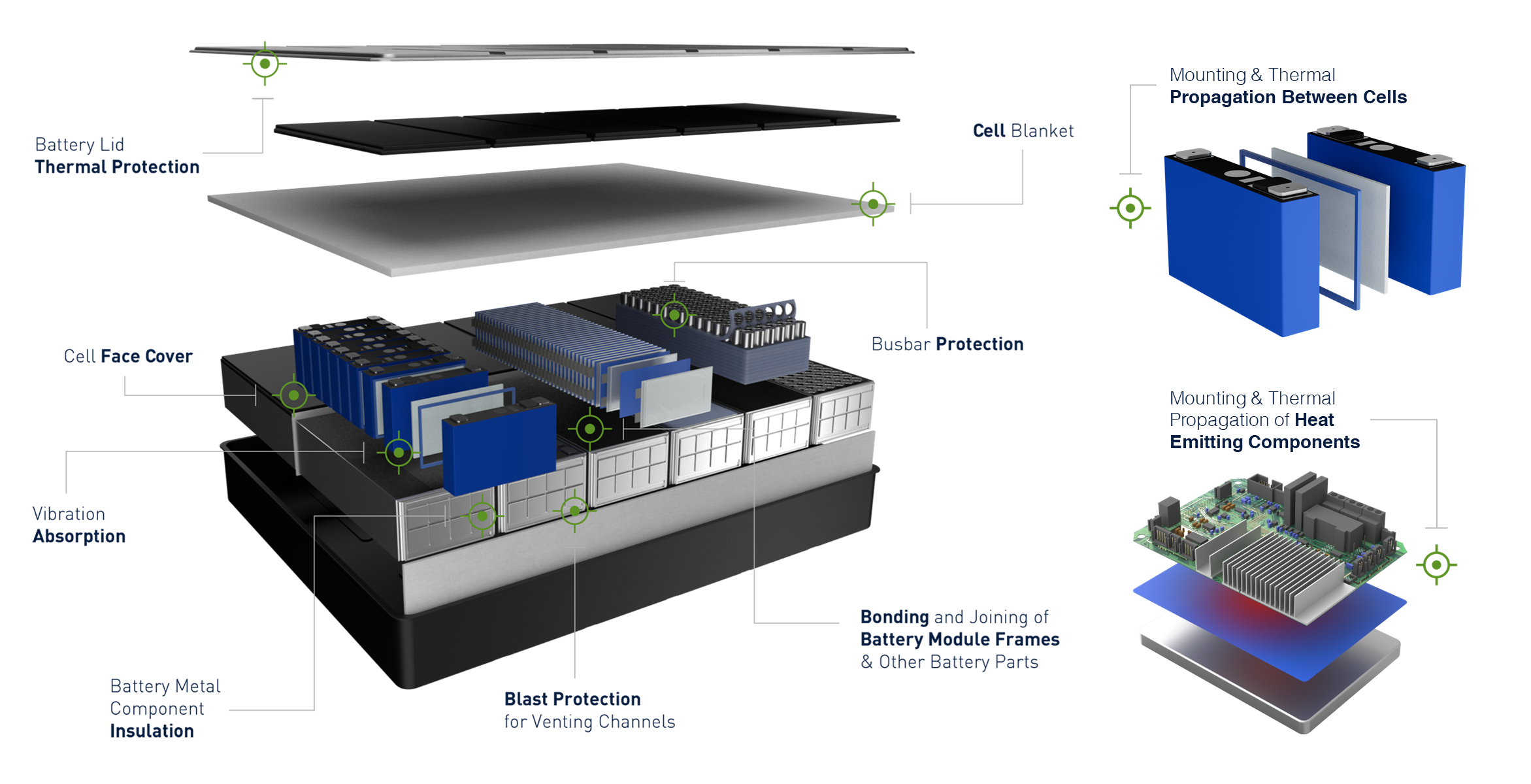

With a focus on improving safety and performance whilst extending battery cell life, we have some of the most effective solutions available for EV battery pack thermal management, and electrical conducting and insulating.

automotive thermal & electrical management

thermal management expertise

thermal management expertiseTecman has a proven track record and expertise in thermal management solutions working with OEM’s and suppliers across the globe. Our experience in this critical area of EV battery projects ensures efficient heat dissipation, contributing to the overall performance and longevity of electric vehicle systems.

Trusted end-to-end Partner

Trusted end-to-end PartnerWe are an end-to-end engineering and manufacturing partner. This integrated approach allows for seamless collaboration throughout the entire EV battery development process, from concept to production, streamlining project timelines and ensuring consistent quality.

Certification & Quality

Certification & QualityOur facility in Leamington Spa, UK, holds IATF 16949:2016 certification. This certification underscores our commitment to meeting automotive industry standards, ensuring that products and solutions are aligned with rigorous quality requirements. With robust systems encompassing APQP, NPI, Engineering Change Control, and Six Sigma, we ensure the highest standards at every stage of your project.

optimised solutions

optimised solutionsWe focus on developing solutions that enhance manufacturing and assembly processes, contributing to increased efficiency and reduced overall costs. This emphasis on cost-effectiveness, without compromising quality, aligns with the automotive industry's need for competitive solutions in the rapidly evolving EV market.

We collaborate closely with our customers, gaining in-depth insights into specific project requirements. This collaborative approach enables customised solutions that meet the unique requirements and objectives of each EV battery project.

By combining innovative conversion techniques with high-performance advanced materials our solutions improve overall performance which is critical for the evolving demands of EVs.

Contact our experts to explore how Tecman's advanced solutions for automotive thermal and electrical management can enhance your application by delivering improved performance and overall cost savings.

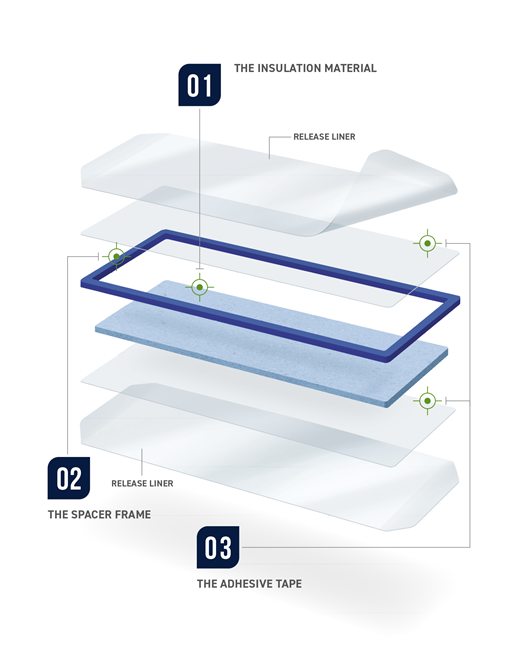

Develop a single manufacturing process for an anti-thermal propagation solution to optimise space between cells and control expansion and contraction to improve cell life and performance.

A highly efficient compact manufacturing process suitable for integrating into existing production facilities, manufacturing Framed ATP Pads in one continuous production run without the requirement of a 3rd party converter.

Cost-efficient manufacture of 36 million OEM approved Framed ATP Pads per year at close proximity to battery assembly plant or at customers' own facility. Superior anti-thermal propagation using advanced technology improves safety and increases cell life.

Tecman's thermal and electrical management solutions for EV battery systems are innovative engineered solutions that utilise advanced materials with thermodynamic and heat transfer properties.

With years of experience addressing the challenges of thermal management across various industries, we have designed and manufactured millions of thermal and electrical management components that are intelligently engineered to meet customer specifications.

Our extensive industry knowledge and expertise in advanced materials and technologies enable us to develop solutions capable of addressing thermal challenges faced by the EV battery sector.

We have a proven track record of delivering value-added solutions to our customers, including automotive OEMs and tier 1 suppliers. By combining our experience and advanced knowledge with a collaborative problem-solving approach, we consistently achieve success.

Our technical team is dedicated to providing support and expertise in material selection and engineering, facilitating superior electric vehicle and battery system development.

Effective thermal runaway barriers are essential for optimising cell performance, longevity, and saf…

Our portfolio of thermal management materials and products include thermal cell barriers, thermal in…

Demands for improved Electric Vehicle performance are increasing and this requires innovation in bat…

After showcasing our advanced thermal runaway barriers at The Battery Show Europe, we share the freq…