Advanced thermal runaway barriers

Extend battery cell life, optimise performance, and improve safety

Effective thermal runaway barriers are essential for optimising cell performance, longevity, and safety of battery packs.

Our OEM-approved thermal cell barriers represent a breakthrough in anti-thermal propagation technology for prismatic, pouch, and cylindrical cells. These advanced thermal runaway barriers address persistent industry challenges while playing a crucial role in reducing overall costs and enhancing profitability for OEMs—all while maintaining uncompromising quality.

Developed at our IATF-certified facility in collaboration with leading automotive OEMs, our solution is used across electric vehicle ranges, providing a superior thermal propagation delay of over 20 minutes. The cost-effective, all-in-one manufacturing system for this technology supports the transition to net-zero by improving the efficiency and sustainability of EV battery production.

anti-thermal propagation technology

Advanced thermal runaway barriers for battery packs

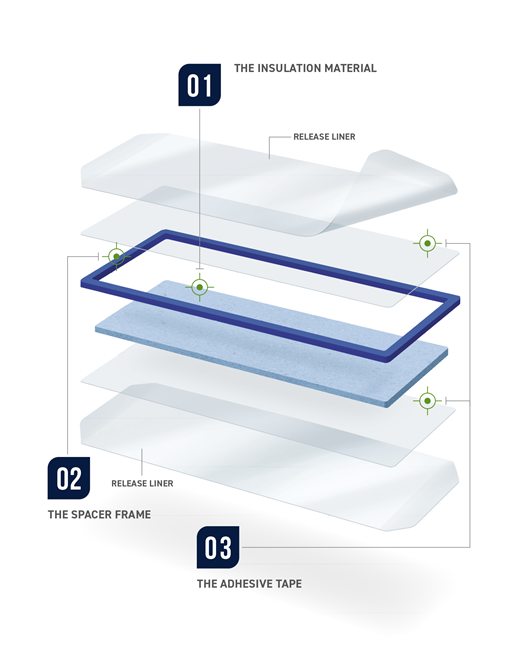

Our ground-breaking thermal runaway barriers, known as Anti-thermal Propagation (ATP) Pads, incorporate innovative features designed to optimise both the performance and lifespan of the cell and improve the overall safety of the battery pack.

Available for prismatic, pouch, and cylindrical cells, our advanced thermal cell barriers prevent or delay thermal propagation from a thermal runaway event.

ATP Pads can be customised for specific requirements and manufactured using an industry-leading all-in-one process, eliminating third-party pre-conversion for efficient, high-volume manufacturing. This approach not only streamlines production, but also reduces costs without compromising quality while supporting sustainability goals by reducing manufacturing and transportation emissions.

Contact an Expert about Thermal Runaway Barriers

Our team are on hand to demonstrate how the advanced thermal cell barrier technology can help you achieve improved battery pack performance while meeting financial objectives.

Enhancing Profitability

efficient manufacturing system for thermal cell barriers

maximised space efficiency

Our state-of-the-art manufacturing system is engineered to deliver significant profitability benefits for automotive OEMs. With a compact footprint, the production line integrates seamlessly into existing clean production facilities or dedicated spaces close to battery assembly lines, maximising space efficiency and reducing facility costs.

Reduced costs

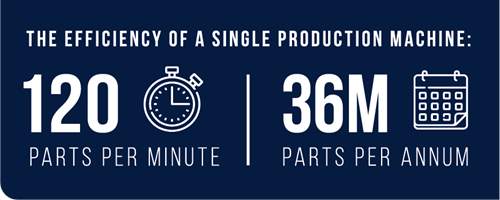

The all-in-one manufacturing system eliminates the need for third-party pre-conversion, which reduces operational costs, simplifies the supply chain, and enhances overall production efficiency. The ability to produce up to 120 parts per minute, with a total capacity of up to 36 million parts per year, ensures high output and continuous operation, minimising downtime and further lowering costs.

Enhanced quality control

Automation within the system not only reduces labour costs but also improves quality control through in-line closed-loop adjustments and 100% part inspection, ensuring consistent, reliable production. The flexibility to handle different materials and part sizes allows OEMs to accommodate evolving battery technologies and specifications without compromising efficiency or quality.

Optimised resource utilisation

This all-in-one process optimises resource utilisation, shortens production times, and reduces material input costs, all while maintaining a high level of output. By situating this compact, high-capacity production line close to battery assembly plants, OEMs can further reduce transportation costs and streamline operations, ultimately enhancing profitability and supporting rapid growth.

fast track development

Tecman’s advanced thermal cell barriers are more than just a concept—they are now in full serial production. This leap-frog development journey allows OEMs to fast-track the adoption of cutting-edge thermal management solutions, significantly reducing R&D costs and accelerating the path to safer, higher-performing EV batteries, while streamlining both the production process and time-to-market.

sustainability benefits

Tecman’s thermal cell barriers are engineered with sustainability in mind by reducing material waste and energy consumption in the production process. The ability to locate the compact manufacturing system in close proximity to battery assembly lines also minimises logistical costs and transport emissions, creating a more efficient and sustainable production line.

Supporting Carbon Neutrality

Optimised production with reduced emissions

Energy Efficiencies

Our manufacturing system is engineered to minimise energy consumption, leveraging highly efficient processes that lower the overall energy required for production. This reduction not only decreases the carbon footprint at the production level but also creates upstream processing efficiencies, leading to hidden carbon reduction benefits throughout the supply chain.

Minimising emissions

The compact design of the production line allows it to be situated directly within battery pack assembly plants. By eliminating the need for long-distance transportation of components, it significantly reduces transportation emissions, contributing to a more sustainable supply chain.

Continuous Production

The continuous operation across shifts maximises resource utilisation, reducing energy and material consumption. The system's compact footprint minimises the need for additional infrastructure, which helps avoid the carbon emissions associated with large complex machinery.

Optimising resources

Our integrated manufacturing process eliminates the need for pre-processed materials, which reduces material waste and streamlines production. This efficiency not only lowers the environmental impact but also optimises the use of materials, contributing to the sustainability of the entire manufacturing process.

We’re Your Solution-Driven Partner

Enhancing Performance, Safety, and Sustainability

thermal runaway barrier

multiple benefits of advanced thermal cell barriers

Multiple functions

- Critical in preventing heat from a cell in a thermal runaway event propagating to neighbouring cells.

- Integrated spacer provides optimal spacing, allowing the insulation pad to provide consistent thermal insulation and effective cell wall pressure over a significantly higher number of cycles.

- Adhesive layers on either side increase the stiffness of the pad and enhance the overall vibration and shock performance.

Streamlines Supply Chain

- The compact production line can be integrated into existing clean manufacturing facilities.

- Can be situated in close proximity to battery assembly plants.

- Highly efficient manufacturing process eliminates the requirement for component parts to be pre-produced as a sub-assembly.

Fully customisable

- ATP pads can be produced in various sizes with or without frames and in multiple material options.

- Suitable for prismatic cells, pouch cells, cylindrical cells and solid state cells.

- Can be used in both EV battery packs and battery storage systems.

case study in action

Delaying thermal propagation by over 20 mins in EV battery packs

challenge

Develop a single manufacturing process for an anti-thermal propagation solution to optimise space between cells and control expansion and contraction to improve cell life and performance.

solution

A highly efficient compact manufacturing process suitable for integrating into existing production facilities, manufacturing Framed ATP Pads in one continuous production run without the requirement of a 3rd party converter.

outcome

Cost-efficient manufacture of 36 million OEM approved Framed ATP Pads per year at close proximity to battery assembly plant or at customers' own facility. Superior anti-thermal propagation using advanced technology improves safety and increases cell life.

Client Testimonials

What our customer partners think

"Tecman took on the challenge of manufacturing a complex multi-material thermal transfer product. Using innovation, engineering skills and advanced manufacturing capabilities, they took the product from drawing through feasibility and onto production level manufacturing.

I would without hesitation recommend Tecman as a manufacturing partner, whatever challenges they face they overcome them."

Chris Hallsworth

Thermal Management Consultant

--

"I would be very nervous of losing the support

and knowledge they carry."

Senior Development Engineer

At Leading Design and Manufacturing Organisation

Partners in success

Leveraging Cross-Industry Expertise

multi-industry approach to sector-specific challenges

Our advanced material knowledge and application expertise spans across multiple industry sectors. This diversity in experience allows us to bring fresh ideas and innovative solutions to sector specific challenges and projects.

<![Body In White 1 Cropped]()

Automotive & Transportation

As a trusted automotive partner, we work with OEMs and tier suppliers across the globe to develop advanced end-to-end automotive die-cut solutions optimised for application efficiency, cost reduction, and product enhancement.

Learn More

<![Electronics]()

Electronics & Technology

Focusing on weight reduction, minimisation, and rapid assembly we have extensive experience in engineering and manufacturing advanced thermal management, bonding, and sealing solutions for the electronics and technology sector.

Learn More

<![Snow Winter Windmill Wind Mast Machine Resized 1]()

Wind Energy

Tecman is an engineering and manufacturing partner at the forefront of delivering innovative self-adhesive solutions for the wind energy industry. Through close collaboration with our customers and their engineering teams, we develop cutting-edge solutions that address the unique challenges within the wind energy sector.

Learn More

<![Aerospace Resized]()

Aerospace & Defence

Increasingly sophisticated military and aerospace systems and devices require greater performance and reliability in the most demanding environments. Every product that we produce is designed and manufactured to perform in every situation, without fail.

Learn More

<![Townsley Covid 0614]()

Healthcare, Medical & Life Sciences

Tecman has been supporting the medical industry for over 30 years, converting FDA approved materials at our advanced conversion facility into die-cut components for diagnostics, theatre consumables, and face and eye protection.

Learn More

<![Construction 2530759 Resized]()

Construction & Infrastructure

Our solutions leverage advanced adhesive tape technology known for its proven reliability and performance. This technology is trusted by global organisations involved in major infrastructure and construction projects.

Learn More

<![Packaging]()

Packaging & Labelling Solutions

We work closely with leading packaging and labelling companies, combining advanced materials and innovative conversion techniques to develop original concepts that add value, reduce costs and enhance finished products.

Learn More