Thermal Management Products and Materials

Thermal & Electrical Management Materials

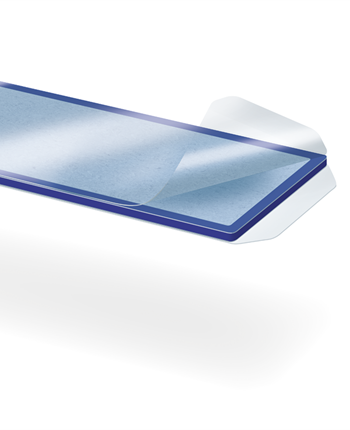

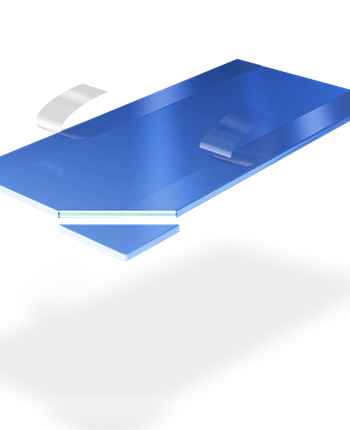

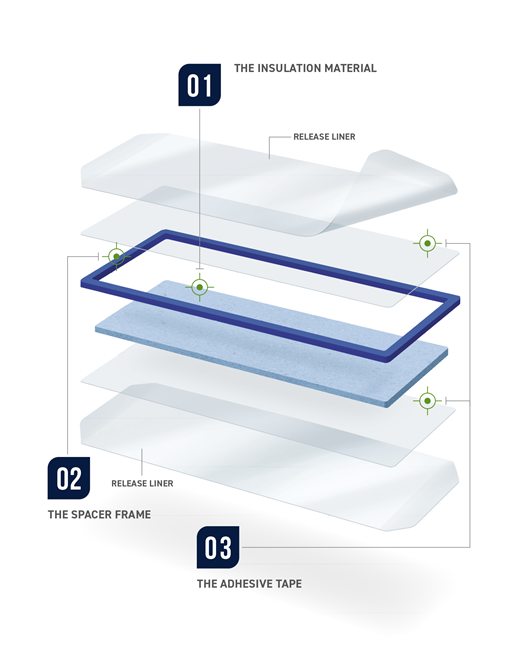

framed thermal cell barrier

Framed ATP Pads are an advanced thermal cell barrier with built-in spacers for prismatic cells designed to delay or prevent cell-to-cell thermal runaway.

Learn More

Thermal cell barrier

Encapsulated ATP Pads are an advanced thermal cell barrier for pouch cells that delay or prevent cell-to-cell thermal runaway.

Learn More

Thermal Interface Materials (TIM)

Sekisui thermal interface materials for advanced thermal transfer solutions between EV battery components.

Learn More

Specialist Thermal Insulation Materials

Ultra-lightweight insulation materials with the highest thermal insulation to weight value of any material.

Learn More

Thermally Conductive Adhesive Tapes

A range of thermal transmission grade acrylic foam tapes precisely formulated to provide semi-structural bonds on various substrates whilst aiding thermal transmission.

Learn More

Thermal Management Graphite Films

Thermal management natural and synthetic graphite materials can be converted into complex die-cut parts to provide thermal interface and bonding properties; reducing hot spots and protecting sensitive components.

Learn More

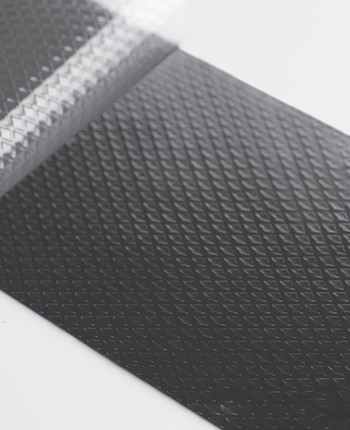

Thermal & Electrical Management Foils

A range of specialist thermally conductive adhesive-backed metallic foil tapes including aluminium, copper, embossed and tinned copper with various adhesives, finishes and conductive properties.

Learn More

Thermal Management solutions

As well as a range of thermal runaway barriers, our portfolio of thermal management materials include thermal interface materials, specialist insulation materials, natural and synthetic graphite, conductive foils, and thermally conductive adhesive tapes. By combining these advanced materials with intelligent conversion techniques we deliver sophisticated thermal management solutions designed to enhance the application.

All our thermal management materials can be converted into bespoke die-cut parts to provide thermal interface and bonding properties, reducing hot spots and protecting sensitive components.

case study in action

Delaying thermal propagation by over 20 mins in EV battery packs

challenge

Develop a single manufacturing process for an anti-thermal propagation solution to optimise space between cells and control expansion and contraction to improve cell life and performance.

solution

A highly efficient compact manufacturing process suitable for integrating into existing production facilities, manufacturing Framed ATP Pads in one continuous production run without the requirement of a 3rd party converter.

outcome

Cost-efficient manufacture of 36 million OEM approved Framed ATP Pads per year at close proximity to battery assembly plant or at customers' own facility. Superior anti-thermal propagation using advanced technology improves safety and increases cell life.