Encapsulated Thermal Cell Barrier

Highly efficient Industry leading manufacturing system for OEM approved Encapsulated Anti-thermal propagation (ATP) pads

Encapsulated ATP pads are an advanced thermal cell barrier that delays or prevents thermal propagation from a thermal runaway event.

Additionally, the thermal cell barriers optimise cell performance through compression performance and can incorporate additional layers to act as a heat transfer.

The Industry Challenge

Improving the safety and performance of battery packs using a cost-efficient cell barrier designed for scale

Battery pack manufacturers, whether automotive or energy storage, face similar challenges with cell life and performance. For thermal barriers between battery cells to be completely effective, they must secure the safety of the pack and provide optimum performance and life expectancy of the cells.

Critically the barrier should delay or prevent the propagation of thermal energy from a cell in thermal runaway to its neighbouring cell. The best-performing barriers will prevent this propagation altogether allowing the cell to expend its energy without triggering a thermal event in the neighbouring cell.

Additionally, the advanced insulation materials that are ideal for this application can be dusty, fibrous and delicate. Therefore, the ideal solution must ensure that no debris or particles from the insulation material are introduced into the battery pack or assembly environment. Whilst ensuring that the delicate structure of the insulation material is not damaged and its performance compromised.

There are various ways that engineers achieve this, however, the challenge is how to produce a debris-free single piece thermal cell barrier optimised for easy assembly, in a cost-efficient production method that delivers extreme high volume.

That's where Tecman comes in.

The Industry Solution:

Cost effective all-in-one manufacturing system for advanced thermal cell barriers

Tecman has developed a highly efficient manufacturing process for the manufacture of OEM approved advanced thermal cell barrier technology. The Encapsulated Anti-Thermal Propagation (ATP) Pad is an advanced single-piece thermal cell barrier manufactured in a cost-efficient production method that delivers extreme high volume.

Encapsulated ATP Pad

The materials used within the Encapsulated ATP Pad can be interchanged depending on the application requirements. We can develop a bespoke solution using a combination of the clients’ specified materials or our own selection of materials.

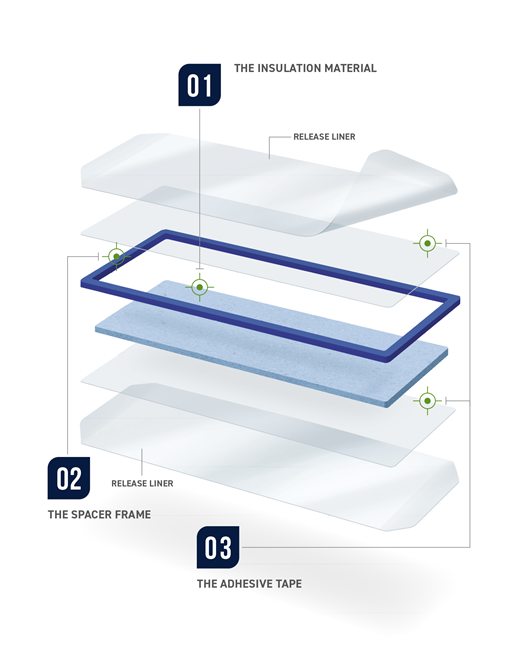

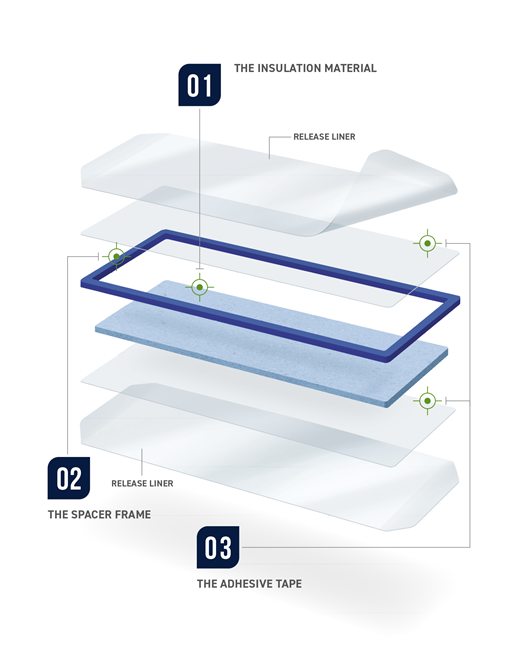

1. Advanced Insulation Materials - The advanced insulation materials used within the Encapsulated ATP Pad provide insulation between cells using anti-thermal propagation technology to prevent thermal propagation in a thermal runaway event.

2. Encapsulation film - Provides dielectric breakdown resistance, reduces debris and aids with the handling of the pads during assembly processes.

3. Double-sided tape for bonding to cell with an adhesive liner. This bonds the pad onto the battery cell to secure it during assembly and improves the vibration and shock performance by holding the cells together adding stiffness to the pack.

The manufacturing process provides the flexibility to customise the materials of the Encapsulated ATP Pad, allowing for customer-specified materials and/or proven materials selected by Tecman's material engineers. There is also the flexibility to incorporate additional layers to act as a heat transfer.

superior ultra-lightweight thermal insulation materials to prevent thermal-runaway

Our Advanced Material Engineers are constantly researching and testing innovative thermal management materials and select the most suitable materials during the development of Encapsulated ATP Pad solutions.

We can integrate customer specified materials and also guide you through the complex material selection process. Previous material recommendations for Encapsulated ATP Pads include insulation materials such as ceramics and aerogels with cutting-edge performance.

These ultra-lightweight insulation materials have the highest thermal insulation to weight value of any material available on the market. They are most effective materials for the prevention of thermal propagation in a thermal runaway event.

The manufacturing System

The compact production line has a very small footprint, making it suitable for integrating into existing clean production facilities or in a small, dedicated production space located close to the battery assembly line.

The process eliminates the need for third-party pre-conversion of the component parts enabling uninterrupted, continuous running. Each machine has the capability of producing up to 120 parts per minute.

By running continuously across shifts, it is a cost-effective, high-volume production line with a capacity to manufacture up to 36 million parts per annum.

| Manufacturing Process Features & Benefits |

||

| Features | Benefits | |

|

ALL IN ONE PROCESS |

|

|

CONTINUOUS PRODUCTION |

|

|

SMALL FOOTPRINT |

|

|

FLEXIBLE MATERIAL OPTIONS |

|

|

MULTIPLE SIZE OPTIONS |

|

Key benefits

Encapsulated ATP Pads

All-in-one Process

benefits

- All-in-one process for manufacturing advanced cell barriers

- Manufacturing speeds of up to 36 million parts per annum

- Continuous cost-efficient production line

- Extreme high volume

- Integrates into existing facilities

- Shortens supply chain

- Flexible solutions tailored to requirements for pouch and solid state battery cell packs

case study in action

Delaying thermal propagation by over 20 mins in EV battery packs

challenge

Develop a single manufacturing process for an anti-thermal propagation solution to optimise space between cells and control expansion and contraction to improve cell life and performance.

solution

A highly efficient compact manufacturing process suitable for integrating into existing production facilities, manufacturing Framed ATP Pads in one continuous production run without the requirement of a 3rd party converter.

outcome

Cost-efficient manufacture of 36 million OEM approved Framed ATP Pads per year at close proximity to battery assembly plant or at customers' own facility. Superior anti-thermal propagation using advanced technology improves safety and increases cell life.

Encapsulated ATP Pad brochure

Solving thermal management challenges with industry leading manufacturing system

Framed ATP Pad

Advanced thermal cell barrier with built-in spacer

for prismatic cells

We also manufacture thermal cell barriers with built-in frames, Framed Anti-Thermal Propagation (ATP) Pads, designed to optimise space between battery cells to improve performance and extend cell life.

The Framed ATP Pad is an advanced thermal cell barrier that incorporates a physical built-in spacer surrounding the thermal insulation pad. During service including rapid charge the cells require space to expand and contract which puts significant strain on the cell.

The Framed ATP Pad provides optimal space to allow for the cell movement and gives a degree of mechanical resistance to the wall of the cell to absorb expansion and support the contraction of the walls in a controlled manner. This enhances cell performance and overall life of the cell.

The all-in-one process for manufacturing Framed ATP Pads is a continuous cost-efficient production line with manufacturing speeds of up to 36 million parts per annum achieving extreme high volume.