Wearable Medical Device Components

Custom die-cut stick-to-skin components for wearable medical devices.

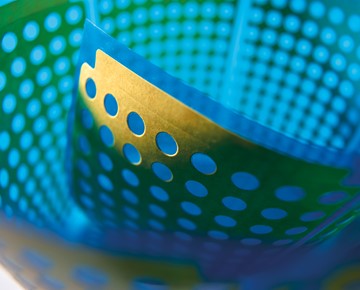

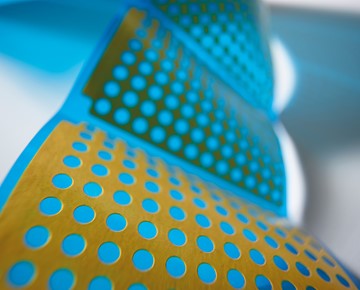

Engineered die-cut medical components

Tecman has been supporting the medical industry for over 30 years, converting FDA approved materials at our advanced conversion facility into die-cut components for diagnostics, theatre consumables, and face and eye protection. As a leading manufacturer of precision die-cut components, we are committed to excellence and continuous improvement.

Through our strategic network of ISO 13485:2003-accredited partners, equipped with ISO 7 Clean Room facilities compliant with ISO 14644:1999, we deliver solutions that meet the stringent demands of the medical sector. Our expertise, advanced capabilities, and innovative approach position us as a trusted partner, consistently exceeding expectations with tailored solutions.

Tecman customers benefit from a trusted UK conversion partner with over 30 years’ experience in supplying self-adhesive die-cut solutions to the medical and healthcare industries:

Our dedicated and experienced support team provide information and guidance during the development of medical die-cut components, from design concept through to delivery.

We provide reassurance of trusted conversion partner producing high-quality product at competitive pricing from our state-of art facility in Leamington Spa, UK.

We manufacture disposable face shields and medical visors at our UK facility in Leamington Spa, with UK sourced materials from a robust healthcare supply chain.

Our high-volume manufacturing facility with innovative capabilities enable the development and manufacture of face shields, medical visors, dental visors, and various eye protection products supplied into medical and healthcare sectors.

Tecman face shields are manufactured to the highest standards using medical grade materials.

Key Features:

Custom die-cut stick-to-skin components for wearable medical devices.

Tecman has a track record of working with diagnostic manufacturers to effectively develop engineered…

Lessons learnt for PPE manufacturers and procurement professionals alike.

Our proven track record underlines our commitment to delivering value-added products with consistent…

13-FL22 MED is a clear double-sided film with a skin friendly adhesive developed for applications requiring direct skin contact.

13-FL23 MED is a clear double-sided polyester film with differential adhesives developed for applications requiring direct skin contact.

27-PU125H MED is a flexible polyurethane film coated with a skin friendly acrylic adhesive developed for applications requiring direct skin contact.

We have the flexibility to convert all our industrial double-sided adhesive tapes into customised solutions for customer specific bonding and mounting applications, available in various formats, including die-cut components, rolls, sheets, and adhesive pads.

Tecman’s range of high performance surface protection film and masking tapes are used to protect surfaces during manufacturing processes in demanding industries such as automotive, electronics, and wind blade protection in the renewable energy sector.

Our high-performance foam and acoustic materials are converted into custom components for a wide range of industries and applications, including sealing and cushioning, through to NVH management in electric vehicle powertrains.

Our portfolio of thermal management materials and products include thermal cell barriers, thermal interface materials and other thermally and electrically conductive materials for critical applications such as thermal management in EV battery packs.