Case Study: Added Value Adhesive Gasket for Automotive Interior

Design & manufacture of a custom die-cut adhesive gasket to bond a plastic component to a vehicl…

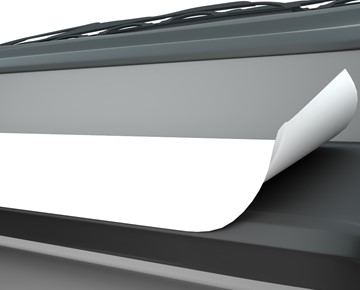

An optimised paint masking solution delivering efficiency and performance improvements in a time-sensitive injection moulder project.

“This project is a great example of how we work with injection moulders, large and small. The customer approached us with a time sensitive challenge and needed support manufacturing components that they could no longer source.

Tecman surpassed expectations, delivering a solution to a tight timeframe that met the customer’s specifications and delivered added value through improved performance and efficiency savings.”

Wayne Matthews, Head of Sales

Tecman worked with the UK division of a major European injection moulder, who provide composite and moulded plastic solutions.

They came to us after their existing supplier was no longer able to supply a specialist die-cut masking component part for use in paint masking. The customer needed to source a new supplier but did not have the exact part specifications or drawings as these were owned by the previous supplier, so needed a partner with relevant expertise and knowledge to support them.

There was also a pressing time requirement, as the customer needed to fulfil existing orders with no drop in quality or performance, so Tecman needed to integrate into existing processes at speed.

In order to develop a solution that met the customer’s specification, our experienced team reverse engineered the die-cut paint masking solution; to understand how it has been constructed and to assess where improvements in performance and efficiency could be made.

We then guided the customer through the material selection process before creating a bespoke solution that met their specification, using fresh drawings to produce laser cut prototypes within a week.

The team fully immersed in the die-cut paint masking solution project, which enabled them to understand the culture of the business and to deliver against frequent tight deadlines, to help ensure the customer maintained continuous supply of their own components, which was critical.

By supporting on the redesign of the part, we also added value by helping unlock tangible savings for the customer in labour cost through application support and price reductions for their preferred materials, which is the result of our material selection expertise and economies of scale – these outcomes surpassed customer expectations. The drawings Tecman developed have also been shared with the customer to help them better understand the component and improve supply chain resilience.

The customer chose Tecman because of our track record of working with injection moulders and our experience within the automotive sector. Being an end-to-end partner meant we brought an understanding of the whole process to the project, including the supply chain, which enabled us to design a part that created efficiency savings and added value to the customer’s product.

We used our expertise in high volume manufacturing to ensure this was built in as a consideration at every stage of the design journey. This approach meant that the end solution was scalable, and avoided the pitfall that some companies encounter of solutions being impractical to produce at high volumes.

As a trusted end-to-end partner, our expertise in addressing challenges faced by injection moulders extends across multiple applications and industries. Contact our experts to discover how our advanced custom solutions can enhance your project by unlocking hidden improvements and efficiencies.

Provides precise paint lines for decorative finishing, non-stretch gives exceptional paint edges.

PVC fine line masking tape provides excellent conformability for detailed edges, conforms to textured surfaces, no shrink, often used for two tone with oven drying.

Economical grade crepe masking tape resistant to 40°C with good tack and removability, for 24 – 48 hour masking.

Premium grade crepe masking tape resistant to 80°C with instant adhesion and excellent removability, suitable for 7 – 10 day masking.

High temperature masking tape for paint shops and high temperature curing with a long term temperature resistance of 140°C, suitable for all oven systems and has excellent removability.

High quality masking tapes covering a wide range of requirements from fine line automotive paint masking through to extra heavy crepe products for masking areas during shot blasting and sand blasting applications.

Design & manufacture of a custom die-cut adhesive gasket to bond a plastic component to a vehicl…

Design & manufacture of a set of custom die-cut shot-blast masking components to deliver efficie…

We worked with a large manufacturer in the construction supply chain on a custom paint masking solut…

Customised, die-cut paint masking solutions to protect components or surfaces during the painting pr…

A vehicle’s paintwork is one of its most distinct features, so it is crucial that contingencies are…

Many of the processes that go into fabricating high-performance vehicles remain largely unsung, prov…

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…

Our proven track record underlines our commitment to delivering value-added products with consistent…