Surface Protection Solutions

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…

Development of an OEM approved solution to protect piano black painted surfaces during automotive manufacturing processes

“This project was a great opportunity to provide an effective protection film solution for a popular high gloss paint finish. We worked closely with the OEM to deliver a cost effective, easy to apply product that surpassed the customer’s expectations.

This project saw the creation of a new bespoke engineered protection film solution and builds on our experience of developing such parts for a range of industries. We have since worked on a number of protection film solutions that have been specified by automotive clients who have been attracted to Tecman's track record, expertise and capabilities".

Wayne Matthews, Head of Sales

Who did we work with?

We worked on a collaborative project involving a major automotive OEM and an automotive PU paint manufacturer. Tecman was approached in 2017, having worked with the automotive OEM on several similar projects in the past.

What was the project?

The automotive OEM approached us with two challenges.

Firstly, they needed protection film for a piano black paint, which is notoriously delicate and easy to mark. Piano black is an accent colour and has become very popular within the automotive industry over recent years due to its high-gloss appearance. Although this looks fantastic on many vehicles, it comes with drawbacks and is highly susceptible to witness marks and adhesive systems on protection films. These parts are therefore susceptible to surface damage throughout the vehicle manufacturing process and during the removal of the protection film.

Secondly, this piano black protection film needed to be used in a bespoke way – fitting a centre console to protect it during assembly but without hindering the work of operators during this process.

Tecman is well known as a materials specialist and manufacturer of advanced, customised die-cut parts. This reputation, and our proven track record within the automotive sector, helped us stand out as well placed to help the major OEM with this requirement.

What did we do?

As with every project for new or existing customers, our engineers took time to understand the automotive OEM’s objectives and technical requirements before designing the bespoke part that met the specification and budget they had set out.

To effectively protect piano black paint, we reviewed and tested a range of cutting-edge films and adhesives and developed a solution that could be applied to gloss painted plastics after painting. This would ensure the part could be protected during the remaining stages of the assembly and manufacturing process. Tecman to speed up the testing process so that products could be assessed within a shorter time frame than would normally be the case.

Applying a film after painting can bring its own challenges, as often a PU paint system is still outgassing for some time. This can result in bubbling if covered in a film too soon after the curing process. The team rigorously evaluated the product to ensure witness marks were not present – this is an important quality control step as incorrect application of a protection film could result in irreversible damage.

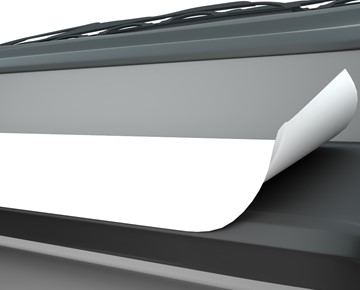

Protection films are a fantastic way of protecting surfaces during production but need to be easy to apply accurately. Tecman devoted significant time and effort into developing processes that enable the manufacture of complex, die-cut films that can be applied accurately, quickly and easily by operators. This significantly reduces processing time and improves efficiency.

The 0250540 automotive protection film Tecman selected for this project has specific properties that mean it can be onto the component, circumventing the outgassing bubbling issue.

It is also extremely tough, so can be kept in place throughout the assembly process and removed cleanly at the dealership, without any adhesive residue remaining on the component. This perfect finish is essential to maximise appeal of final products within dealership showrooms.

Tecman engineers then used their deep understanding of the selected protection film to design the bespoke die-cut solution to protect the centre console of the vehicle. We considered the specification and assembly and testing of the parts to gain insights on how to best protect

Innovative features we included in the design enabled the OEM’s production team to test certain components during assembly for function and safety, for example enabling the film to be pulled back to test a compartment door without reducing the protection offered by the film to the components.

What did we achieve?

Tecman added value through an in-house knowledge and understanding of materials and through the selection of adhesives and films that could offer the right degree of protection for piano black paint. Tecman engineers have multi-sector die-cutting experience, which enabled them to consider a range of advanced solutions for the shaped centre console component.

This led to the selection of a high performing protection film for piano black paint and the design of a solution that surpassed the automotive OEM’s expectations. Key to this was Tecman’s ability to understand the journey that the mould needed to take and the various considerations that needed to be addressed.

The advanced solution supplied by Tecman protected the centre console throughout the assembly process and avoided hindering assembly staff working on the vehicle production line – meeting key requirements set out by the OEM. Ultimately, this protection film went on to achieve OEM approval and was specified in OEM drawings and on projects.

Our value is as an end-to-end partner that can provide manufacturing capabilities and consultancy expertise.

The OEM team used Tecman as a source of knowledge and expertise due to our deep understanding of automotive manufacturing and assembly processes. An understanding of the journey of a centre console and the testing and quality processes enabled Tecman to select the best materials and adjust for specific considerations.

Tecman's surface protection and masking solutions are designed to meet the most exacting requirements and cover a wide scope of applications from protecting delicate surfaces through to heavy-duty masking tape for shot blast and sandblast applications.

We deliver intelligent die-cut protection solutions with innovative design features, customised liner configurations and presentation styles designed to add tangible value, improve application efficiency and reduce overall costs.

White protection film designed for delicate lacquered, painted and uncoated high gloss plastic and metal components suitable for long-term outdoor exposure.

OEM approved protection film for the protection of sensitive surfaces during transportation. Due to the good UV resistance, the film can remain on the surface until the arrival at the end customer.

Self-adhesive film that has been developed for the protection of various surfaces, especially interior parts of automobiles like carpets, dashboards and door sills during storage, assembly and transportation. Consisting of a PE backing coated with a water based acrylic adhesive.

Provides reliable protection for painted surfaces susceptible to damage. Due to the good UV-resistance and perfect paint compatibility, it’s the most reliable way to protect cars during the transportation process.

High performance surface protection films, including products with Automotive OEM approvals, covering the widest scope of applications, from the complex requirements of the automotive industry to anti-fingerprint films for touch screens and LCD displays.

High quality masking tapes covering a wide range of requirements from fine line automotive paint masking through to extra heavy crepe products for masking areas during shot blasting and sand blasting applications.

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…

Customised, die-cut paint masking solutions to protect components or surfaces during the painting pr…

Development of a specialised custom masking solution for a leading injection moulder to streamline t…

The sensitive surface of Piano black high gloss finish is prone to mark easily during the removal of…

Tecman has been working in close collaboration with a major Automotive OEM and PU paint manufacturer…

Tecman's semi-automated jig and fixture equipment are designed for cost-effective and simple applica…

A major OEM approved another Tecman automotive surface protection film for use on painted plastic in…

Our proven track record underlines our commitment to delivering value-added products with consistent…