Alfa® Acoustic Materials

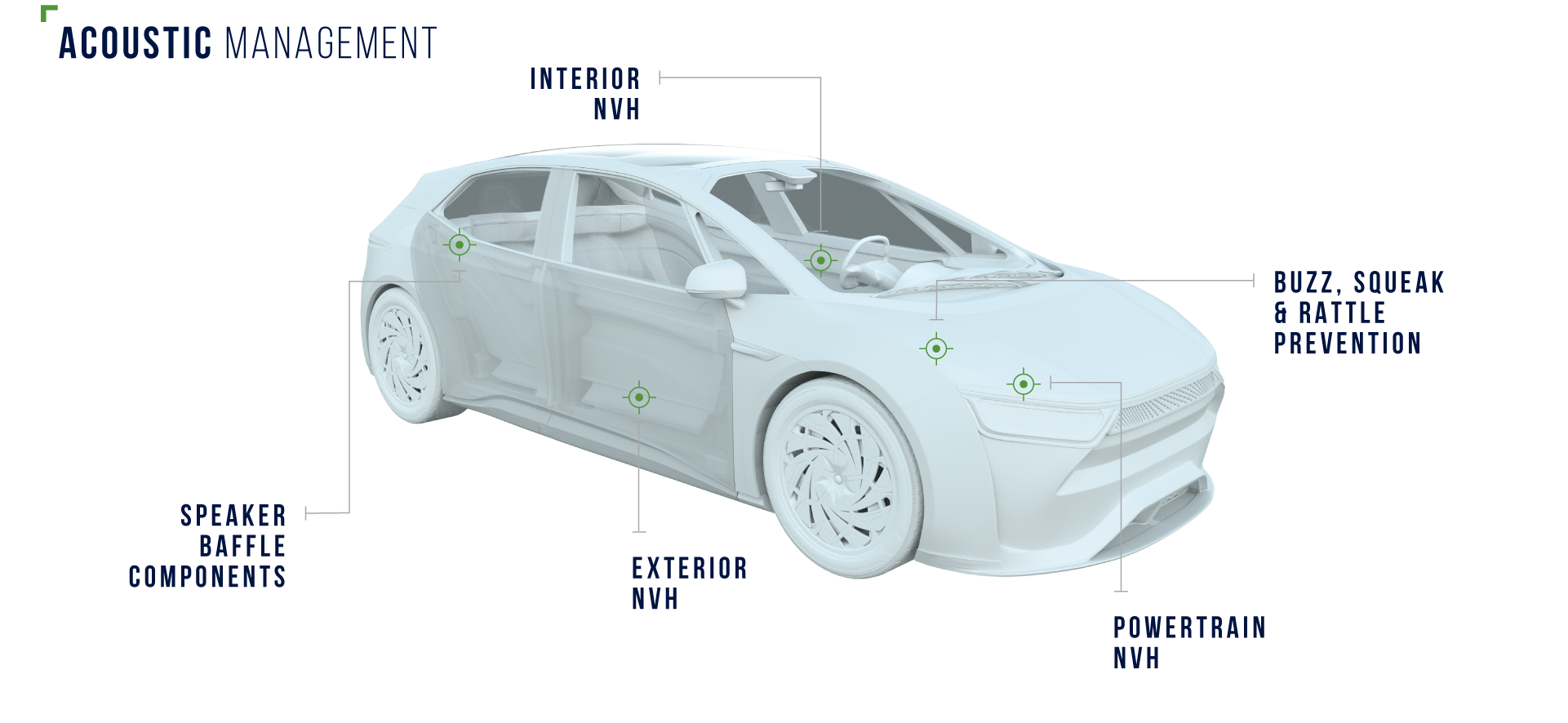

Alfa® Technology Acoustic Insulation Materials for NVH management throughout the vehicle, including …

Engineered Acoustic Insulation Components for Automotive NVH

The absence of low-frequency engine noise brings new challenges with EV and PHEV due to higher-frequency sounds becoming more prominent from areas such as inverters, battery charging and electric motors.

The requirement for quieter, lightweight, and more energy efficient vehicles requires NVH components to become lighter and more efficient.

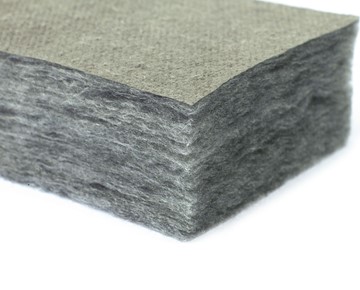

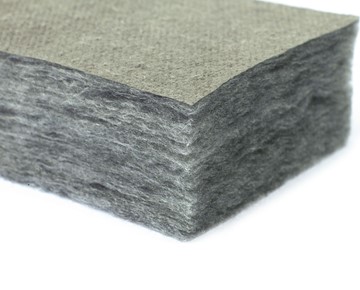

Tecman’s Alfa® Technology acoustic insulation materials combine sophisticated multi-layer laminates, lightweight dampening, and advanced scrim materials with innovative manufacturing techniques to produce some of the most advanced NVH management solutions for electric vehicles.

NHV & Acoustic Solutions

quality assurance

quality assuranceOur facility holds IATF 16949:2016 certification, affirming our commitment to rigorous quality standards. We also employee robust systems including APQP, NPI, Engineering Change Control, and Six Sigma to consistently meet the highest industry standards.

Advanced materials

Advanced materials We stay ahead with the latest technologies and materials. Our use of cutting-edge innovations in NVH solutions guarantees enhanced performance and long-term effectiveness.

Partnership Approach

Partnership Approach Our customers' success is our priority so we work closely with automotive OEMs and customer partners to develop bespoke acoustic management and NVH solutions that align with unique project requirements.

Continuous Improvement

Continuous ImprovementAt Tecman, we're all about continuous improvement. Our dedicated team is always exploring new ways to refine and enhance automotive NVH solutions. Choose Tecman for solutions that not only meet standards but set new benchmarks.

We collaborate with our customers to acquire in-depth insight into specific project requirements. This approach enables the development of customised solutions that meet the unique requirements and objectives of each automotive project.

By combining innovative conversion techniques with high-performance acoustic materials we develop some of the most advanced NVH management solutions available.

Contact our experts to explore how Tecman's advanced solutions for automotive NVH and acoustic management can enhance your application by delivering improved performance and overall cost savings.

Requirement for 100% absorption coefficient between 800 - 2500Hz due to gas rush for an existing NVH application where too much noise was getting into the cabin and the original solution did not meet the specification set out by the OEM.

Combination of zone coated adhesive tape laminated to acoustic insulation material and die-cut to shape. Presented with a complete, single peel release liner for improved liner removal.

OEM NVH component with exceptional NVH properties and bond strength, easy and quick application with consistent, successful results.

The Material Selector contain sample swatches and comprehensive technical data for our complete range of automotive acoustic and foam materials.

Our range of Alfa® Technology acoustic insulation materials includes sophisticated multi-layer laminates, such as advanced scrim materials, impregnated layers, and ultra-light-weight heat reflective materials. These advanced properties provide a high degree of flexibility when developing bespoke NVH management solutions.

A range of foam materials with advanced properties for acoustic applications including anti-rattle and anti-squeak pads.

Partners in success

Alfa® Technology Acoustic Insulation Materials for NVH management throughout the vehicle, including …

There are many potential sources of NVH in automotive vehicles. Tecman supply a range of solutions f…

In the automotive engineering industry, noise, vibration, and harshness (NVH) refer to a vehicle’s l…

Automotive insulation solutions from Tecman are all designed to provide highly efficient acoustic ab…