Die-Cut Components Designed for Performance & Efficiency

5 Ways Tecman's Die-Cut Parts Unlock Improvements in Your Manufacturing Processes

Custom die-cut parts can be seen as simple consumables, sourced to fulfil a single binary purpose; bond, protect, seal, insulate or conduct. But have you ever looked at these components as potential drivers of operational efficiency?

In modern manufacturing every second on the assembly line, every extra step in the process and every millimetre of material waste directly impacts your bottom line. What if the small die-cut components that you source also helped to tackle a big problem like assembly and manufacturing efficiency?

When Die-Cut Components are designed around your specific processes, engineered with an understanding of your challenges and priorities, they can become drivers of efficiency and performance. Simplifying processes, removing bottlenecks, eliminating waste and saving time and the list goes on.

Here are five ways die-cut parts from Tecman are engineered

to make a huge impact:

1. Reduce application time

Die-cut adhesive parts can be developed to streamline production and simplify complex manual steps. By gaining a deep understanding of your application, we can implement clever design features or inexpensive application features that enhance and speed up your application process. Sometimes even a small tweak results in a huge efficiency gain.

Slashed application time by 43%:

A customer’s project involved long paint-masking application times. We observed their process and spotted that the narrowness of the tape was adding significant extra time into the task. By providing a bespoke tape width tailored to their specific product, application time was slashed by almost half, reducing labour costs. (Learn more about this project)

2. Seamlessly integrate into your processes:

A custom die-cut part should be optimised for your manufacturing workflow. Once we understand your process, we can identify how best to integrate the component, often introducing the part with no extra steps or delays required.

Seamless integration into a high-speed line:

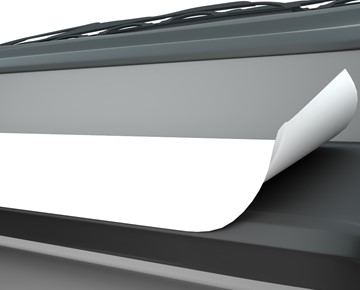

A manufacturer faced critical product damage during transportation. We visited the site, observed the line, and identified a small "window" where a temporary protection film could be applied. We designed a multi-section die-cut protection component with custom features that could be applied in seconds, adding zero delays to their production while eliminating transport damage. (Learn more about this project)

3. Reduce quality issues and rework:

The right component removes the inconsistencies and human error inherent in manufacturing and assembly processes. We provide parts engineered around your application and product for effortless accuracy, and reliable performance that reduce quality issues and the need for costly rework.

Eliminated expensive rework and downtime:

A customer was experiencing frequent weld damage during shot-blasting due to inconsistent manual masking. Our engineers designed a complete set of bespoke masking components supplied on a user-friendly sheet with an "application map." This improved operator efficiency and eliminated the errors causing rework. (Learn more about this project)

4. Solve downstream issues:

By taking time to understand how the part we supply fits into the whole assembly process and how it’s used in the supply chain we can incorporate fixes to eliminate downstream issues into the part design. This ensures that the component simplifies and supports the assembly process and improves reliability and performance.

Protected surfaces without hindering product testing:

A customer needed to protect a high-gloss piano black finish on an automotive centre console through a long assembly process without hindering operators. We added perforated sections and tabs to the film, allowing operators to pull back specific areas for safety testing without reducing the protective effectiveness of the component. (Learn more about this project)

5. Reduce waste:

We don't believe in one-size-fits-all solutions; we carefully consider your specific application and usage requirements to develop a component that perfectly fits your needs. This approach naturally reduces waste and inefficiency. Additionally, high waste can often be directly addressed by increasing precision and part tolerances, maximising material usage and ensuring accuracy throughout the assembly process.

Reduced waste by five-fold:

A customer had a 10% scrap rate on high-cost aluminium components due to inconsistent automated application of a die-cut self-adhesive part. We stepped into the project and after making several changes we were able to produce parts to tolerances twice as tight as originally requested. This reduced the scrap rate from 10% to just 1–2%. (Learn more about this project)

Unlock Performance and Efficiency

With Customised Die-Cut Parts from Tecman

It's easy to accept a certain level of waste, rework, or manual "workarounds" as the cost of doing business. But as the examples above show, those compromises can often be avoided by developing the right component.

We believe that you're right to expect more from your die-cut parts. By collaborating with Tecman, you gain a partner that can consider your entire application to supply high-precision components that can add value where it matters most: the efficiency and performance of your operations.

All it takes is a quick chat with our Technical Team.

We offer a complete review of your current solution at no cost or obligation. Let us demonstrate how we can solve your challenges with a die-cut part optimised for your processes.

Learn more about die-cut parts from Tecman

5 tips for custom die-cut adhesive part success

5 insightful tips to help you navigate your custom die-cut adhesive part project with ease and succe…

How can injection moulders optimise sub-assembly efficiency?

Optimising sub-assembly processes is a key challenge for many businesses. Learn how we work with man…

Fast, Clean, and Reliable Bonding Solutions

Advanced adhesive bonding solutions have transformed modern product assembly, facilitating new appro…

Rapid and Precise Application of Automotive Protection Films

Tecman's semi-automated jig and fixture equipment are designed for cost-effective and simple applica…

Adhesive Tape Solutions

We manufacture custom die-cut adhesive tape and engineered adhesive tape solutions

Surface Protection Solutions

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…

Thermal Management Applications

Advanced thermal management solutions using high-performance materials

Die-cut Paint Masking Solutions

Customised, die-cut paint masking solutions to protect components or surfaces during the painting pr…