Tecman automotive

Tecman Launches Successful ATP Technology into Europe

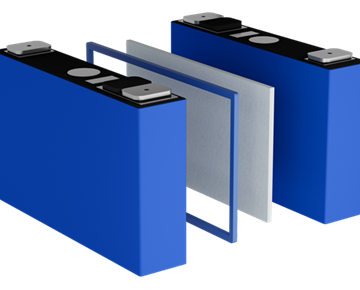

Tecman announce the launch of its Anti-thermal Propagation technology into Europe at The Battery Show Europe in Stuttgart. This ground-breaking thermal cell barrier technology can enhance cell life and optimise performance, while increasing the thermal propagation delay to over 20 minutes.…

Pioneering scalability & innovation in EV thermal management

Demands for improved Electric Vehicle performance are increasing and this requires innovation in battery pack thermal management. Learn how we support OEMs to address thermal management challenges in battery packs by developing new solutions using existing and proven materials in more innovative ways.…