Case Study: OEM Approved Protection Film

Developed a solution with a major automotive OEM to protect piano black paint during manufacturing p…

Rapid Development of a Custom Surface Protection Component for the EV Supply Chain

"Our customer's product was on the verge of full production when early runs revealed an issue: transportation was causing scratches and damage. We were asked to quickly develop a protection film solution to prevent this damage and seamlessly fit into their existing processes. The customer was extremely pleased with the final component and it was a genuine pleasure to help them overcome this challenge.”

Wayne Matthews, Tecman Project Lead

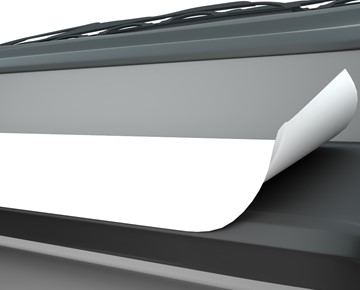

A manufacturer within the EV charger supply chain faced a critical problem: their product parts were incurring damage during transportation. Specifically, components were moving in transport, leading to scratches on a matt-finish substrate — a crucial element for the final product's attractive aesthetic.

After exploring various options, the customer determined that a custom temporary protection film component offered the quickest and most effective solution. They turned to Tecman for a robust protection film solution that would completely eliminate transportation damage while ensuring they could still meet their strict production and delivery schedules.

The solution needed to meet other key requirements:

To provide the most effective support, we immediately visited the customer's site. This allowed us to observe their manufacturing process firsthand, directly examine the product, and assess the damage to truly understand the challenge.

The textured matt substrate of the product required a protection film with a specific tackiness level: a sufficient tackiness to adhere sufficiently to withstand friction from moving parts during transport, yet crucially, leave zero adhesive residue upon removal by the customer.

Leveraging our deep expertise in adhesives and materials, we swiftly identified a suitable protection film that performed exceptionally on the matt substrate. We were able to dispatch the first prototypes the very next day after receiving the initial enquiry.

As with all our projects, we dedicated time to fully understand the customer's specific challenges and identify opportunities to add significant value to their processes and final product, and built these insights into the part design.

Collaborating closely with the customer, we pinpointed a small window within their existing manufacturing process for application of the die-cut protection film. We then added features into the part design to enable effective and accurate application of the part in just seconds, ensuring no risk of delays to the production line.

To perfectly conform to the product's complex geometry, we divided the protection film into a small number of sections. We also incorporated additional design features to guarantee optimal and complete surface coverage with every application.

Tecman's custom die-cut surface protection solution delivered precisely what the customer needed, eliminating all transportation-related part damage. Our quick and responsive service enabled the customer to meet their original production and delivery schedules without interruption.

Additionally, our Tecman protection film component enabled complete protection of the product’s surfaces with a fast application process that fit seamlessly within the existing manufacturing process.

Faced with unexpected product damage during transportation and a tight production schedule, the customer needed a proven partner who could deliver a rapid, custom solution. Tecman's proven expertise in custom surface protection components and solution-driven approach made Tecman the ideal choice.

Our ability to select the right protection film for the challenging substrate, coupled with our collaborative approach to designing a precise, die-cut component, delivered tangible value where it mattered. Our focus on seamlessly integrating the solution into their existing manufacturing process ensured a cost-effective and efficient outcome that eliminated damage without disrupting their deadlines.

We support our customers through every stage, from material selection and design phases to choosing the right manufacturing processes. This ensures the delivery of an optimised, cost-effective solution designed to effectively overcome challenges and deliver tangible benefits.

If your application could benefit from cost savings, process improvements, material enhancements, and product advancements, reach out to our experts to discover how we can support your application.

Developed a solution with a major automotive OEM to protect piano black paint during manufacturing p…

Design & manufacture of a custom die-cut adhesive gasket to bond a plastic component to a vehicl…

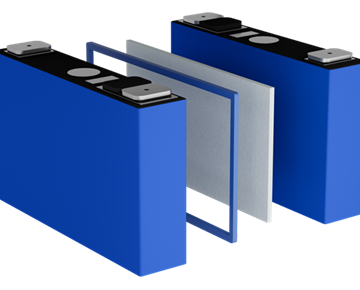

A concept-to-manufacture solution for a major automotive OEM to delay thermal propagation in EV batt…

Advanced solutions to protect surfaces and components during manufacturing and transportation proces…

High performance surface protection films, including products with Automotive OEM approvals, coverin…

Tecman has been working in close collaboration with a major Automotive OEM and PU paint manufacturer…

Tecman's semi-automated jig and fixture equipment are designed for cost-effective and simple applica…

Our proven track record underlines our commitment to delivering value-added products with consistent…