Advanced Thermal cell barrier innovation

Newly developed process makes Framed ATP Pads a reality

Customers will know that when it comes to tackling persistent industry problems, we take a contrarian approach and consider challenges afresh.

We take this approach to both products and processes, so automotive OEMs and battery manufacturers familiar with our thermal management offering will be delighted to know that we launched our newest innovation at Battery Cells and Systems Expo.

High Volume Manufacturing system

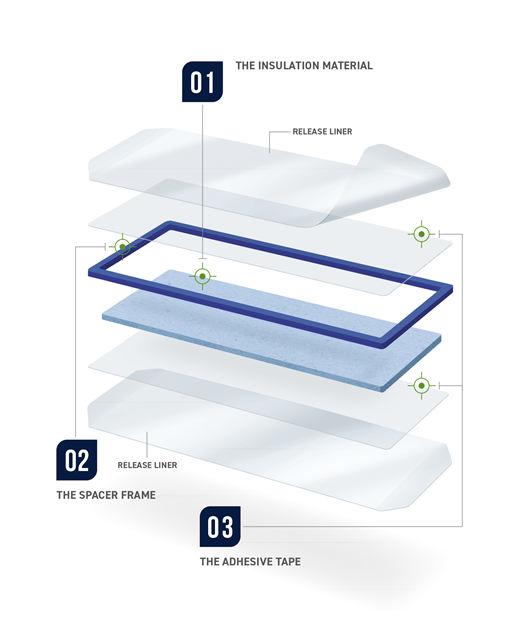

Tecman’s engineers have spent the last 18 months developing and patenting a single continuous production process that enables the high-volume manufacture of Framed ATP Pads for the first time. Improving on thermal cell barriers, this advanced framed solution incorporates a built-in spacer that surrounds the insulation pad to improve the performance and safety of batteries.

This helps prevent thermal propagation by providing optimal spacing, which allows battery cells space to expand and contract, and provides a degree of mechanical resistance to the cell wall.

To date, cell barriers with built-in spacers have been complex to manufacture because they require multiple parts. It has prohibited the development of this design to date, so the whole team is delighted to be the first to bring this innovation to market.

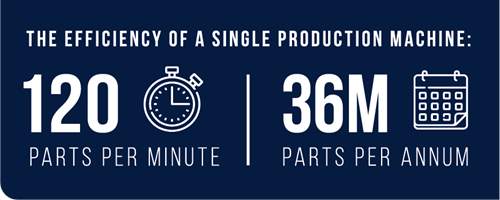

Single continuous production process

Tecman’s new process has been developed as a single, continuous production process, eliminating the need for third-party pre-conversion and reducing costs by unlocking manufacturing speeds of up to 120 parts per minute, cementing our position as a high-volume manufacturer.

This process is a significant innovation for our customers, who will now be able to take advantage of the Framed ATP Pad’s advanced features in a more cost-effective way, and at a significantly higher volume than previously possible.

Find out more

You can find out more about how we tackled the industry challenge for manufacturing framed thermal cell barriers product page:

Framed Anti-thermal propagation solution

Thermal management case study

Preventing thermal runaway in electric vehicle battery packs

Case Study: Advanced Thermal Cell Barrier for EV Battery Packs

A concept-to-manufacture solution for a major automotive OEM to delay thermal propagation in EV battery packs.

View Case study