3M™ VHB™ tape solution

What is VHB™ Tape and what is VHB™ Tape used for?

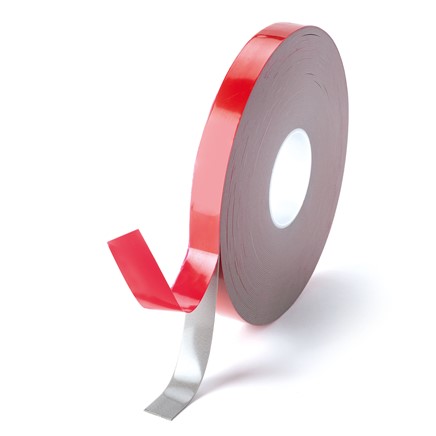

3M™ VHB™ Tape

3M™ VHB™ tapes have been used extensively throughout manufacturing industries since the 1980s. 3M™ VHB™ tapes seal, bond, and attach a wide variety of materials, including plastics, metals, and glass.

Explore our range of Very High Bond Tape

They are used in many bonding applications, both indoor and outdoor, and are often selected as an alternative to liquid adhesives and mechanical fasteners due to their very high bond.

What is VHB™ Tape?

3M™ VHB™ tape uses a viscoelastic acrylic foam in the construction of 3M™ VHB™ tapes. The viscoelasticity provides the foam with the unique properties of stress dissipation and energy absorption. The advanced acrylic chemistry provides exceptional durability and performance.

Properties of 3M™ VHB™ tape

3M™ 9473 - Clear VHB™ Adhesive Tape

The properties of 3M™ VHB™ Tape come from a combination of different foams, colours, adhesives, and release liners and include:

- Adhesion to differential materials

- High tensile strength

- Conformability

- High shear

- High peel adhesion.

3M™ VHB™ Applications

The versatility of the 3M™VHB™ tapes enables their use in a vast range of applications, some of which are listed below.

Automotive

3M™ VHB™ tapes are used extensively within the automotive sector due to the adhesive system providing the highest level of pressure sensitive adhesive (PSA) bond. The solid core of a VHB™ tape provides extremely high cohesive strength whilst maintaining sufficient movement to tolerate different rates of expansion and contraction. Recent product development includes thermally conductive VHB™, adhesion at 0˚C and adhesion to LSE substrates.

The tapes provide various bonding solutions including:

- Plastic to metal

- Glass to metal

- Metal to metal.

Applications within the vehicle include:

- Interior trim mounting

- Exterior trim mounting

- Component attachment

Further to providing a clean, precise bonding system, VHB™ tapes absorb vibration and help to enhance fuel and weight efficiency whilst also improving assembly and manufacturing processes.

3M™ VHB™ GPH-060GF Adhesive Tape

Electronics

Rapid developments within the electronic industry, including increasingly smaller and more lightweight compact systems, have been aided in no small way, by the comparable rapid developments within VHB™ adhesive technology.

Manufacturing processes are made simpler and product designers are given more creative freedom due to the many benefits of using 3M™ VHB™ tapes over traditional bulky fixing methods.

Televisions, smartphones, tablets, etc. all benefit from the use of 3M™ VHB™ tapes. The tight seal ensures water and dirt are prevented from entering the electronics and using the tapes to attach metal and plastic parts eliminate the need for additional large parts to cover bulky fasteners.

Signage

Mechanical fasteners were traditionally used to hold signs together, but they are prone to rust and damage in harsh conditions. High performance bonding tapes provide a cost effective and quick result for the signage industry by eliminating the need of labour-intensive operations such as drilling holes. With fewer structural weak points and due to the adhesive layer spreading stress evenly, 3M™ VHB™ tapes provide a stronger and more durable bond.

3M™ VHB™ tapes can be used both internally and externally due to the UV resistance levels, ensuring longevity without requiring repair or to be replaced entirely.

3M™ VHB™ Tapes Available from Tecman

3M™ VHB™ tapes are a proven and trusted solution for a wide range of bonding requirements, and a core selection is available from Tecman.

| Product Name |

Colour | Thickness |

|---|---|---|

| 3M™ 9473 - CLEAR VHB™ Adhesive Tape | Clear | 0.25mm |

| 3M™ VHB™ GPH-060GF Adhesive Tape | Grey | 0.60mm |

| 3M™ VHB™ GPH-110GF Adhesive Tape | Grey | 1.1mm |

| 3M™ VHB™ GPH-160GF Adhesive Tape | Grey | 1.60mm |

As a leading adhesive tape converter, we provide a large range of bespoke die-cut adhesive solutions designed to optimise assembly and manufacturing processes.

We have the capability to supply nearly all our adhesive tapes, including 3M™ VHB™ tapes, as die-cut parts. Our purpose built, state-of-the-art conversion facility includes high speed precision rotary die-cutting equipment, multi-layer lamination, Inline Corona Treatment and advanced slitting and sheeting methods.

Unrivalled Technical Support

By combining our innovative processes with comprehensive industry and application knowledge, we support the specific needs of our customers and provide high levels of technical and product support. For support with your application:

Contact us

3M™ and VHB™ are trademarks of 3M™